Machinist

0 readers

0 users here now

From Newcomers to Old Timers, a community united by the Industry of Machining

Rules Don't post illegal stuff

Don't post Porn (no sexy aluminum surface finishes don't count)

Don't be an asshat (harassment, bullying etc.)

If you're going to post NSFW stuff, flag it as NSFW, It's ok to post shop Screwups (blood/cuts) just make sure to flag it as NSFW

and Finally make sure to have a good time :D

founded 1 year ago

MODERATORS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1

23

24

25

view more: next ›

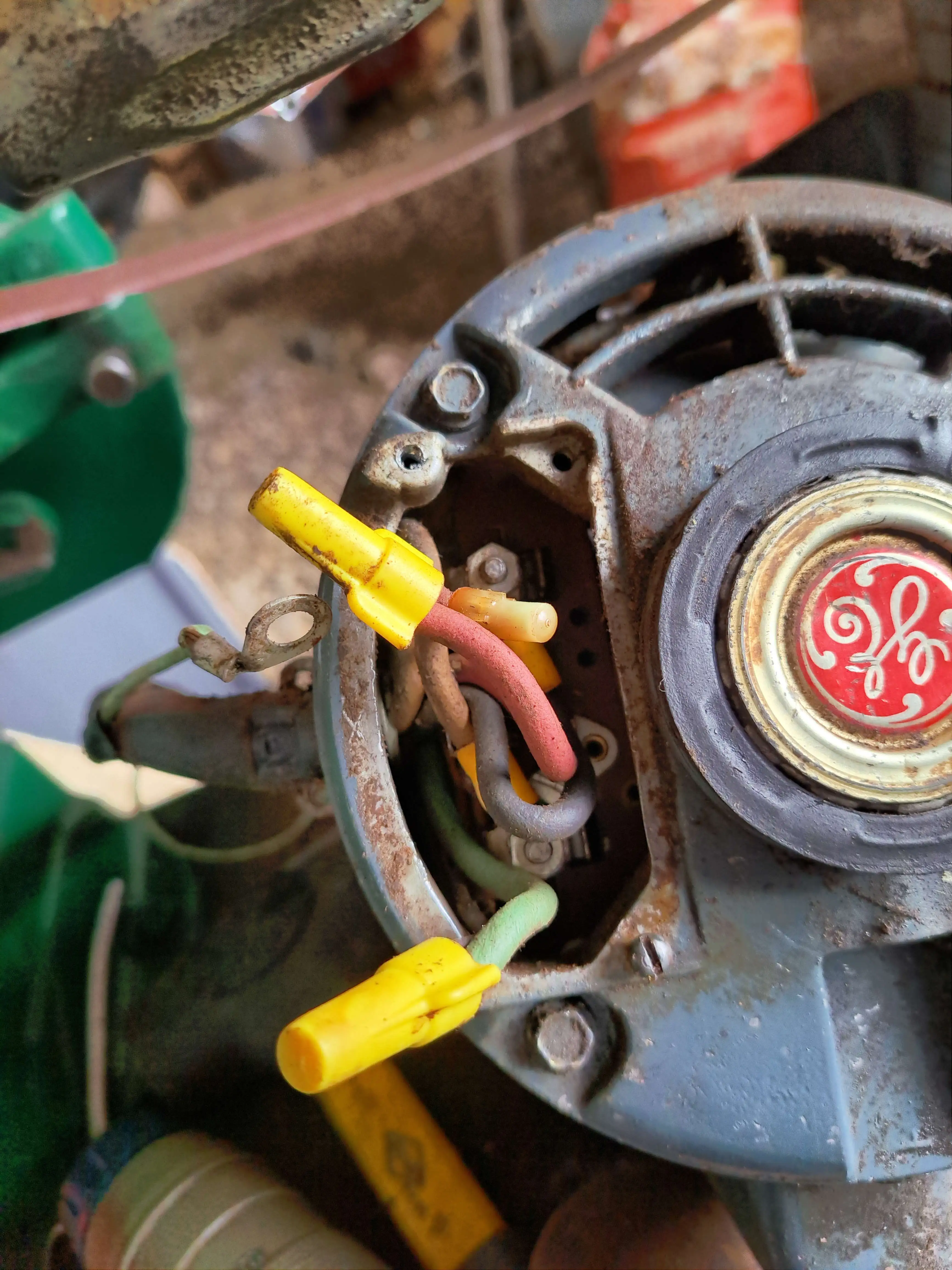

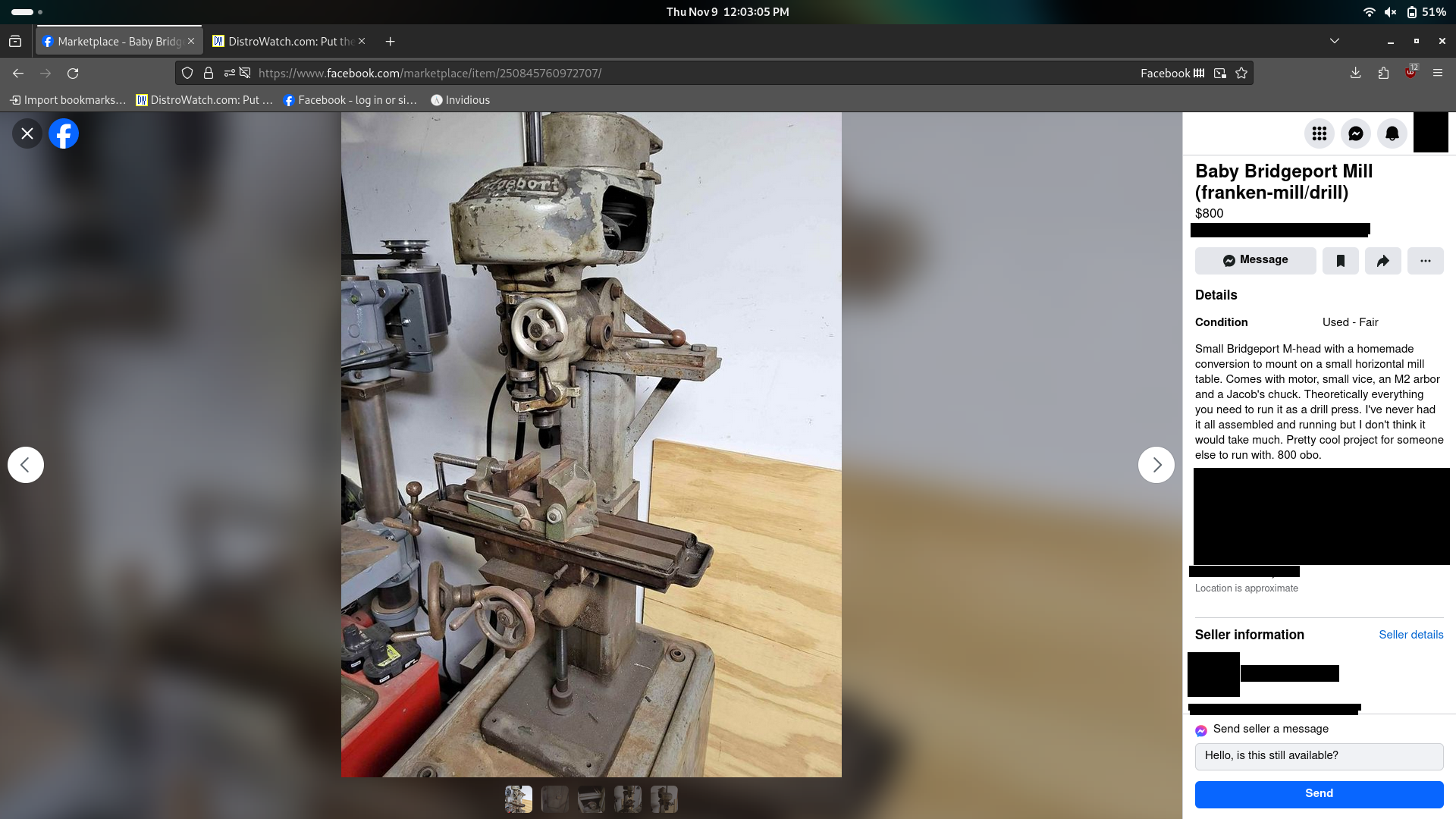

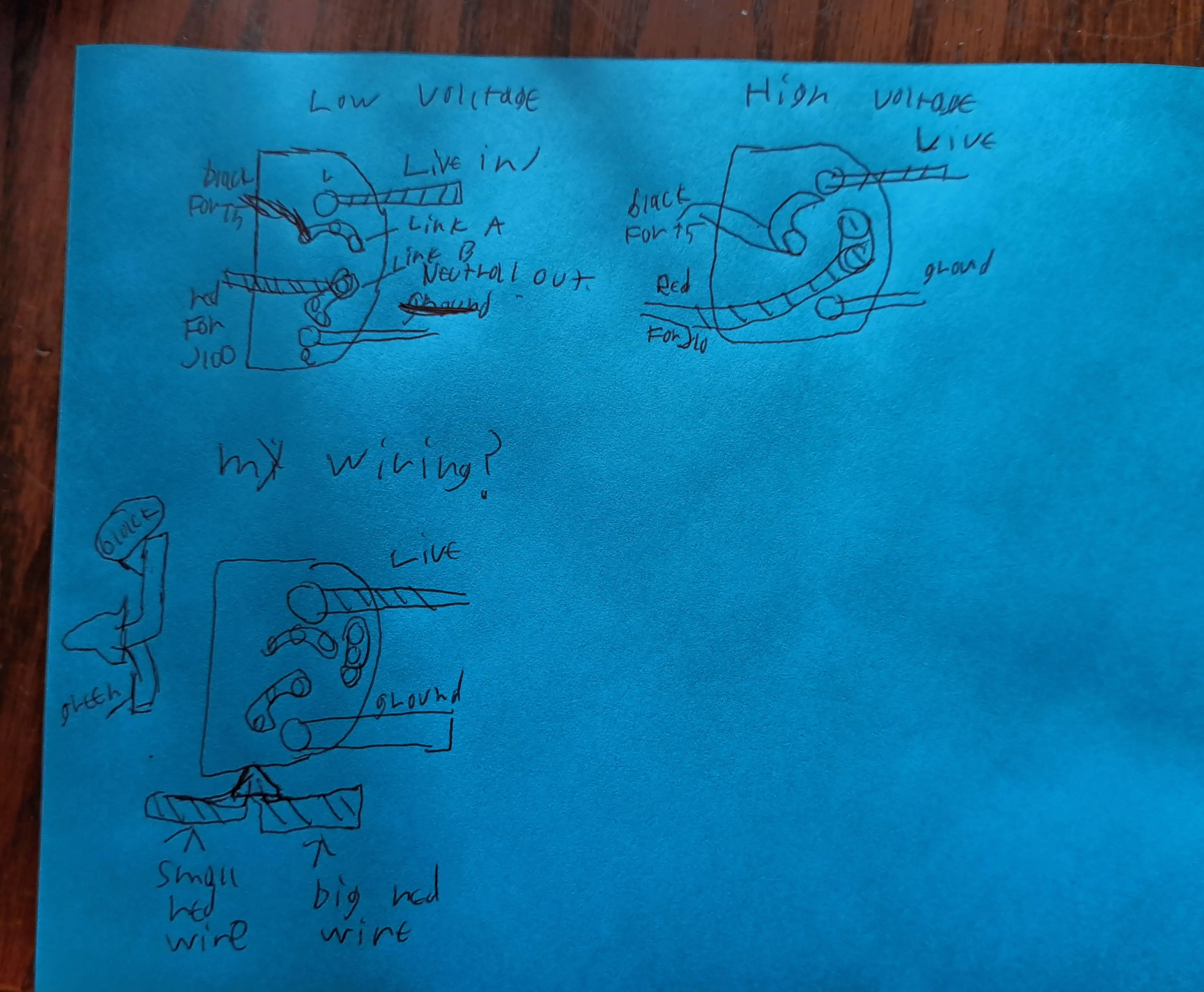

as-well as pictures of the original wiring and board

as-well as pictures of the original wiring and board