3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Pressure advance will solve some of your issues here. When reaching a corner, the head slows down but the filament is still pushed too fast and so it overflows. Pressure advance (in Klipper) can compensate for that.

I'll check that out. I installed klipper yesterday for S&G -- actually quite liking the flexibility it gives me. I see the guide.

Welcome to the deepest rabbit hole in 3D printing! Klipper is nice on the surface and absolutely mind blowing when you dig deeper. If you’re programming savvy, you can make it do basically anything. You can even install a script that runs shell scripts on the pi from the printer. You could make it control your coffee maker via home automation if you wanted. Lol. Anyways. Pressure advance is the key here.

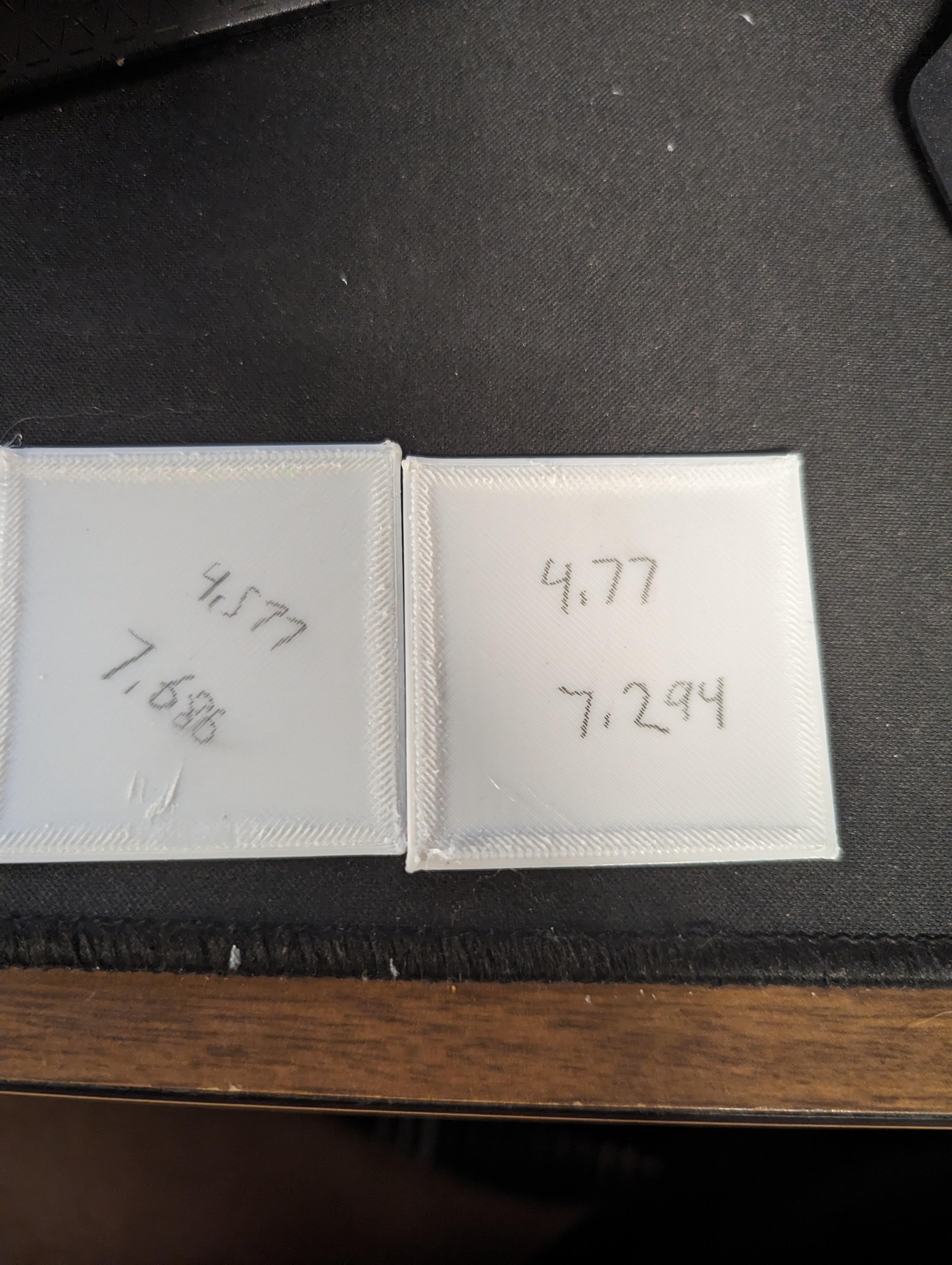

Oh boy... Yes scripting comes easy to me. It's why my default is openscad for making 3d models. :). I'm printing the pressure advance cube model now.

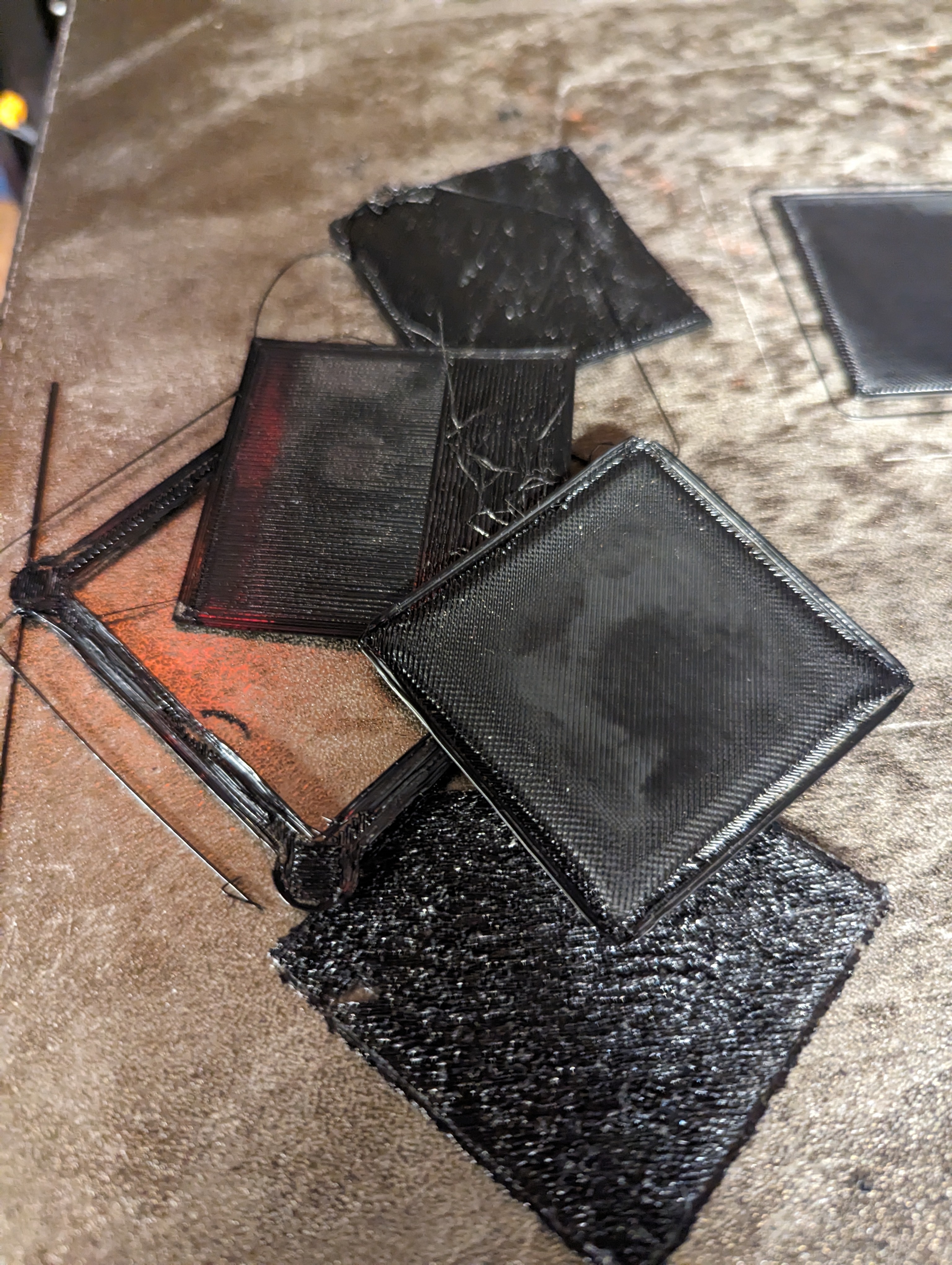

So... I still have some tuning.

I learned that you need to adjust retraction and z offset again after implementing pressure advance.... But I'm close now.