3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

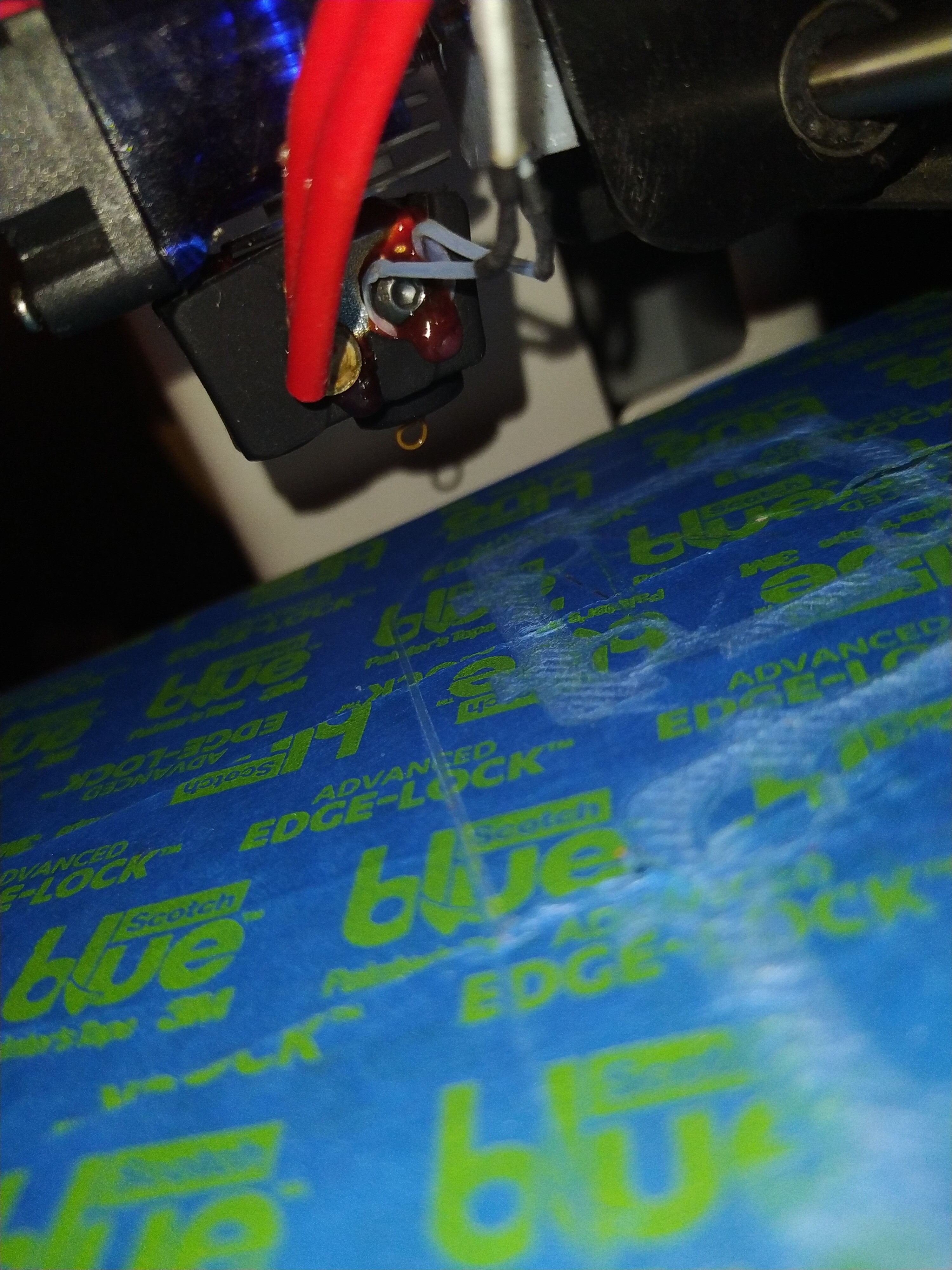

Remove the rubber boot. Is it clean or covered in filament? My guess is, as others have said, the nozzle is loose. It should not be snug against the block but against the other feed pipe. If filament oozes out the sides of the threads, it might get pushed around the inside of the boot and come out the holes in the top.

It was likely a loose nozzle that wasn't properly heat tightened.

For those who don't know, after screwing the nozzle in cold, crank the hotend up to max (or hotter than you ever plan to print by about 10C) and tighten the nozzle again. The thermal expansion is different between an aluminum heat block and a brass nozzle. The extra tightening while hot can overcome this problem.

In my experience the issue is more commonly because the heat break is not threaded into the block far enough to begin with. What then happens is the nozzle bottoms out on the block before making contact with the heat break. You should think of the block as more of a coupler, and want the heat break and nozzle to press into each other within the block.

That is true, without a doubt. What I am saying is in addition to that.

Aluminum will expand more than brass when heated. There will be a gap created between the nozzle and the heat break when heat is applied. The block is a coupler, yes, but it is also a shrink fitting by default.

Thermal expansion is fun. ;)