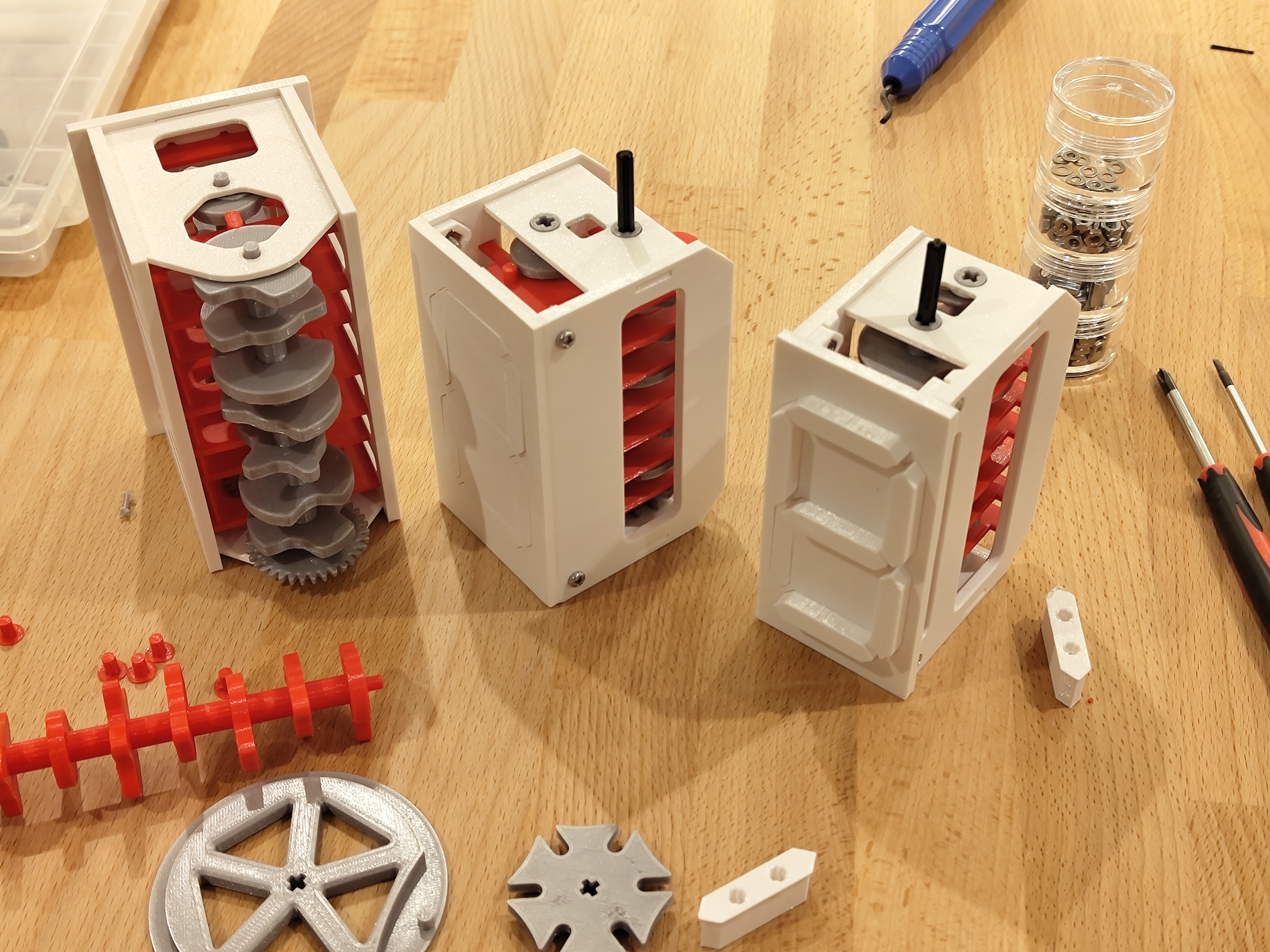

Are those LEGO-compatible axles?

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: !functionalprint@kbin.social or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Yes! 🤓

Awesomeness. Please show us a video of the end result!!

Insanely cool, thanks for sharing! Gives me some fun ideas...

Just yesterday youtube showed me this video and I thought to myself what a waste it is to use 30 servos for a project like this:

https://youtu.be/YQLStT4RXVo?si=wXzEu28u1hp5dKQr

Your solution is so much cooler.

This video was the inspiration for my project!

Yep. I thought of this video as well!

This is a much better engineering solution. Only requires 4 motors.

I'm testing a geneva drive (you can see it in the front in the photo), that should allow me to reduce the number of motors even further. I think I can get it down to two, maybe even one.

Oh that gearbox on the left?? I was just thinking that you could setup some gears similar to a analog clock to use only one motor. Does the geneva drive support snapping into position? With analog you'd want smooth motion, but here you'd want stepped positions. The snap is what makes this build so satisfying to me.

There is no snapping, but the geneva drive will stay locked in position when it is not moving. The thing that I haven't figured out is how to get the 3 to go back to 0 after 23:59, it needs to skip the numbers 4 to 9.

The thing that I haven’t figured out is how to get the 3 to go back to 0 after 23:59, it needs to skip the numbers 4 to 9.

Ok thats making my brain hurt. I'm clearly not a mechanical engineer!

Just make it turn back by 3 clicks. If you’re watching the clock closely enough to notice at midnight you should go to bed anyway 🤷♂️

Seriously though, awesome project!

Wow, never occurred to me before, but this is such an elegant, and simple solution.

Here is an alternative Piped link(s):

https://piped.video/YQLStT4RXVo?si=wXzEu28u1hp5dKQr

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.

Genious idea! Now all you have to do is print the segments in a transparent plastic, black the complete front, and backlight the module.

Dang, camshaft + Geneva is really obvious in hindsight, cool.

New Lemmy Post: I'm working on a mechanical seven segment display (https://lemmy.world/post/11967566)

Tagging: #3dprinting

(Replying in the OP of this thread (NOT THIS BOT!) will appear as a comment in the lemmy discussion.)

I am a FOSS bot. Check my README: https://github.com/db0/lemmy-tagginator/blob/main/README.md