I am in the process of buttoning up a Nitehawk conversion on my Voron. I also replaced my extruder thermistor with an OE replacement purchased from a reputable vendor.

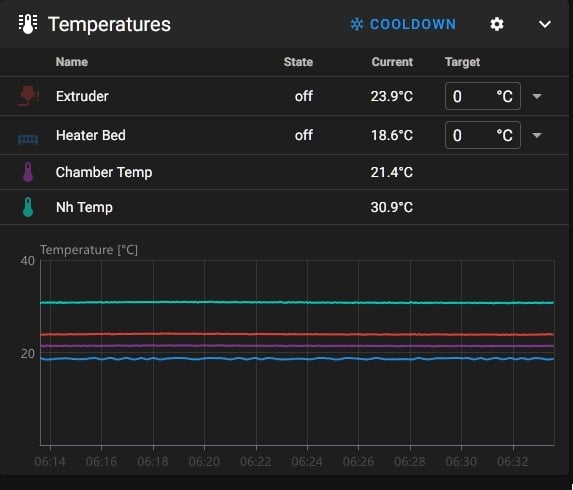

Post setup, my heated bed is reading spot on (it's 18.3 C in my basement aka 65 F). I verified that my extruder is also at ambient temperature by wedging a Thermapen under its silicone sock and letting it acclimate for 10 minutes. The I'm not sure why the extruder would be reading high.

I bought a spare thermistor and wired it in. The result was identical.

Thoughts? Ideas? I'm pretty sure I have the Nitehawk and thermistor set up correctly.

[extruder]

step_pin: nhk:gpio23

dir_pin: nhk:gpio24

enable_pin: !nhk:gpio25

heater_pin: nhk:gpio9

sensor_pin: nhk:gpio29

pullup_resistor: 2200

sensor_type: ATC Semitec 104NT-4-R025H42G`