True, but those things are achievable for "normal" people without having loads of money to begin with...well, maybe less so in the US where education is so expensive compared to other places.

Black ended the challenge having completed 10 months, with just 60 days left to run. He had managed to make a grand total of $64,000.

Pretty damn far from a million, but much more than many make in a year still. I do wonder if he used contacts/network he made while wealthy, that would easily completely invalidate the point he was trying to make.

Garmin is pretty much gold standard when it comes to sports tracking. Most other brands are a step down, and I imagine a FOSS watch like the bangle.js is a significant step down from Garmin watches WRT sports tracking.

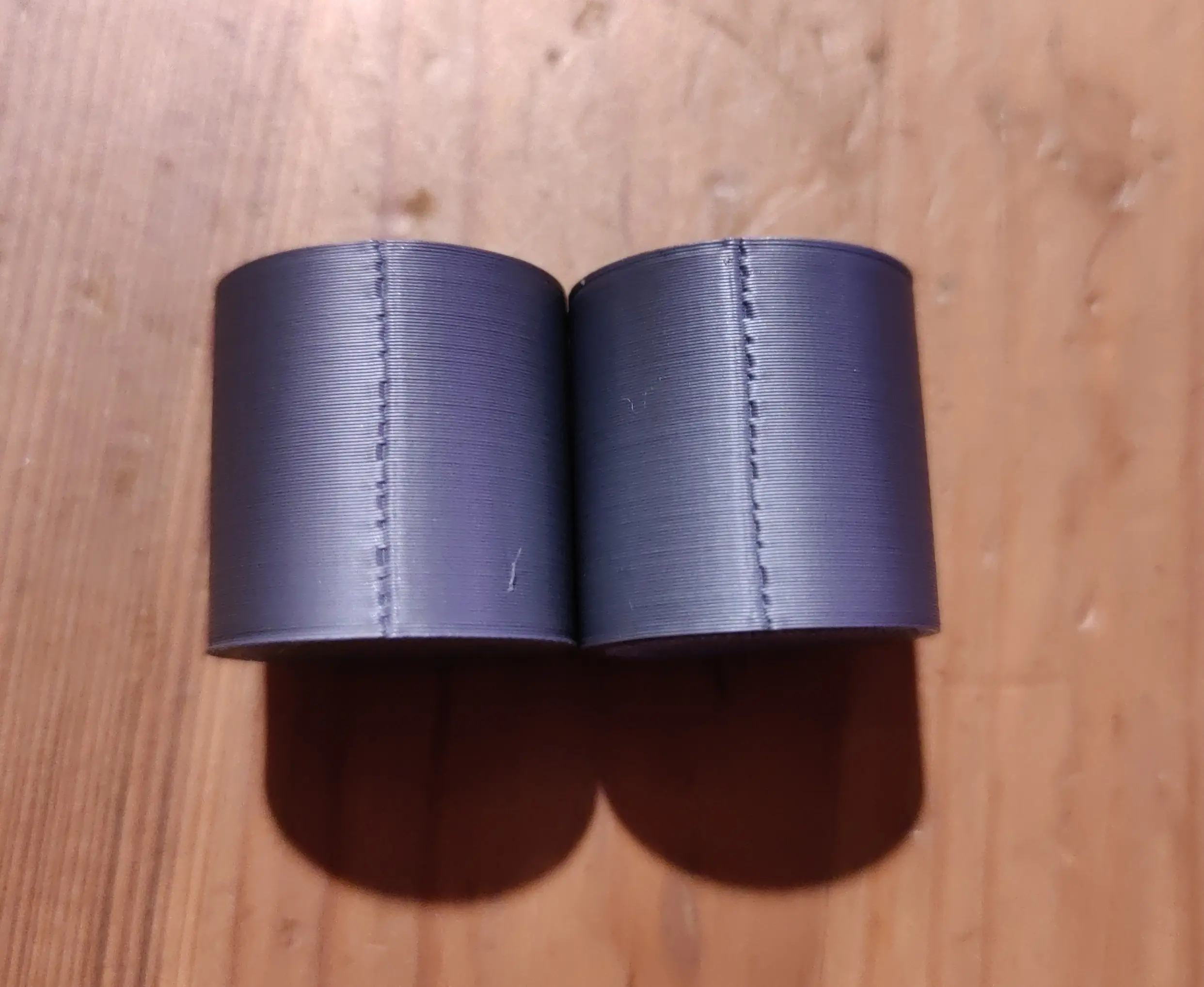

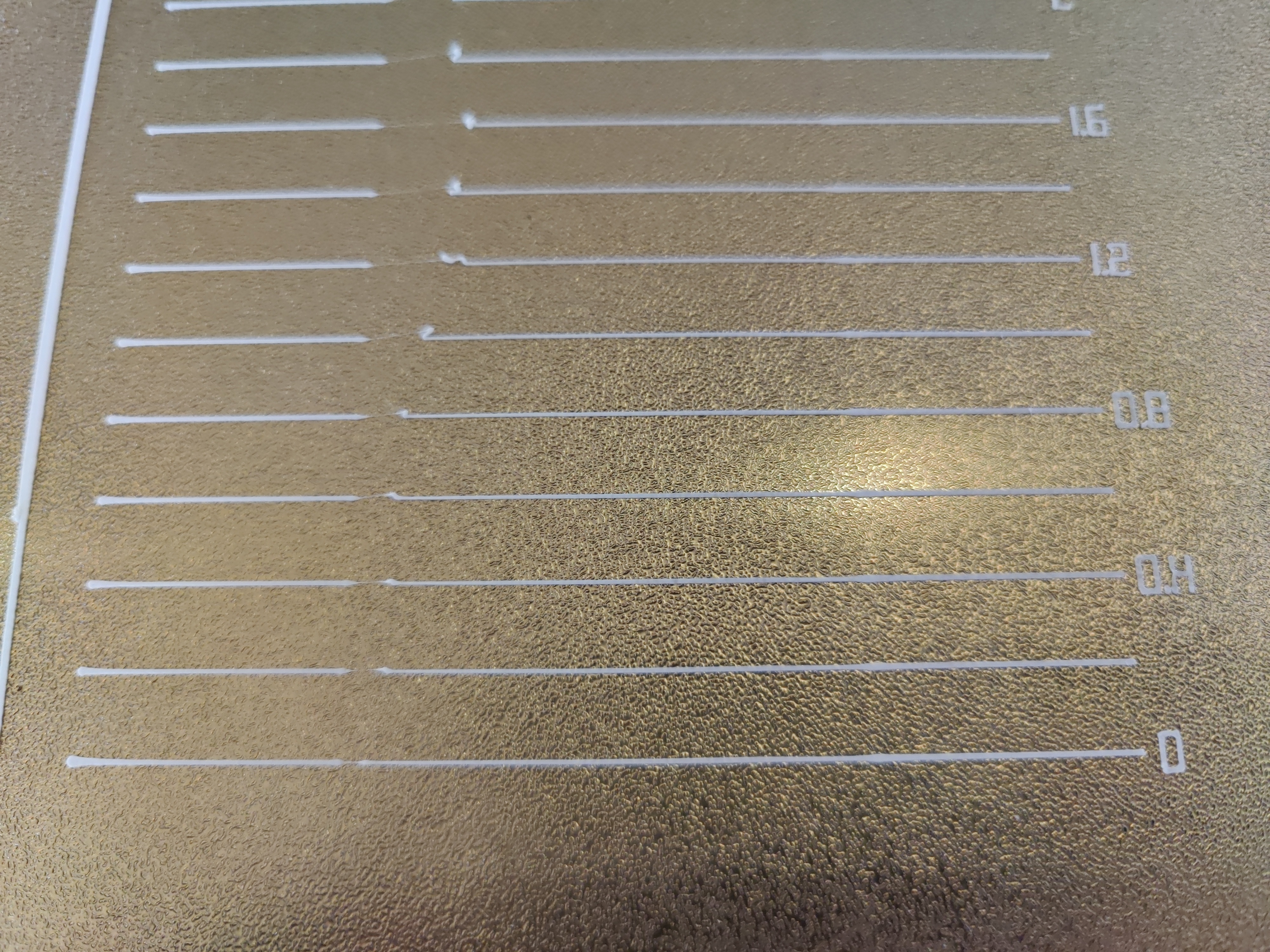

The solution was more cooling. It was warping due to too much heat, I increased cooling to 100% and reduced overhang speed slightly and it now prints well.

Both ASA and ABS are approved materials. ASA has higher heat defection than ABS, should be easier to print and it smells significantly less when printing.

Fans are completely disabled, except for overhangs and bridges. If I disable fans for overhangs and bridges, they sag like crazy.

I doubt draft shield is going to do anything, the printer is already completely enclosed in a tent. I have around 50-55°C inside the tent.

Edit: I tried a re-print with less cooling for overhangs, it seems to exacerbate the issue significantly.

Piped isn't working for me either anymore. I was using piped.adminforge.de before, but I've tried other instances too without any luck. It won't load play any videos at all. I can search and find stuff without issues, but I can't play anything.

I just swipe left for "back" (android), and I can access everything just fine, it just closes the TOS. Just do that every time I open the app, works like a charm.

I known perfectly well what position CATL is in on the battery market...but this is still nothing but PR bullshit, there is nothing but buzzwords in the link, no data or anything to backup their supposed breakthrough. PR "articles" like this are worth nothing, it's an advertisement and nothing more.

The "article" is just a load of PR bullshit without any details whatsoever or any real info...so maybe they're just doing that...maybe not...it's impossible to tell from the link provided.

You're just making it ~~worse~~ better.

Wow yeah that first one is pretty terrible looking 😅

I'm decently pleased with mine though, but I'm really looking forward to the quality on the voron. I actually already have "the filter" on my current printer (slightly oddly placed in the tent, but it works), and I just connected it directly to the printer PSU and manually turn it on/off with a toggle switch.